Twenty meters high

In Korea, little land is available for building, as 75% of the country is covered by mountains. Harim cleverly solved this problem by designing a five (!) story high building, attached to the existing plant, extending their existing 80,000 m2 (861,111 sq ft) production area to 150,000 m2 (1,614,586 sq ft). Spacious air chill tunnels, which use proven DownFlow Plus technology, will be positioned on the top floor.

A Marel overhead conveyor system distributes broilers to all departments, keeping all processes completely in-line. The system features ATC technology (Automatic Tension Control), which makes for increased reliability as well as reduced wear and tear. In Harim's Iksan plant, ATC allows a spectacular height difference of more than 20 meters (65 ft) to be bridged, necessary to reach all stories!

Software and maintenance

Of course, such an extensive poultry plant can't do without the necessary software control. Innova food processing software will ensure the overall monitoring of all equipment installed in the Marel lines at Harim.

Because of the size of the plant, preventive maintenance is an important issue to protect the four lines from unnecessary downtime. During the first years, Marel's field service engineers will pay regular visits to the Iksan plant, a wish clearly expressed by the Harim Group.

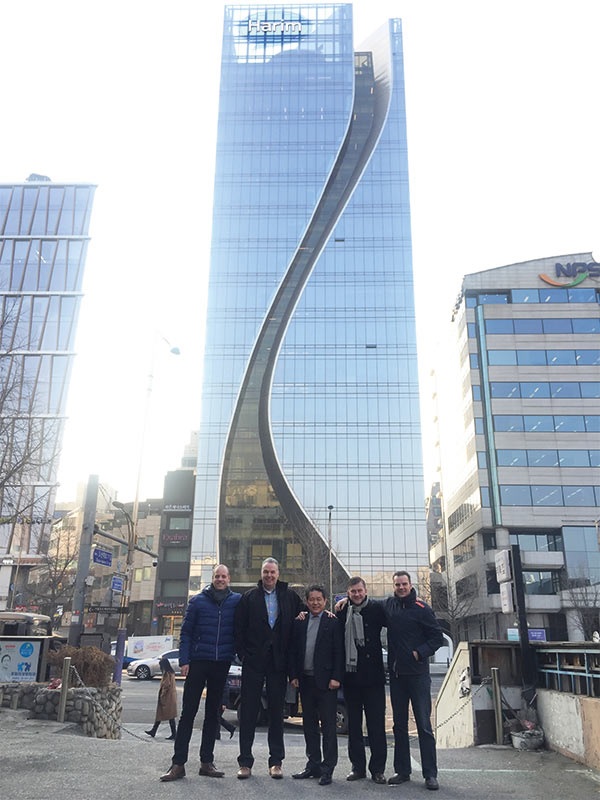

A vision of openness

Chairman Kim has a clear vision of the industry, "Harim wants to be more open about poultry processing. That is why we open our doors not only to our customers but also to students and others who are interested in poultry processing. We like to show how our high-speed lines succeed in producing good quality and healthy chicken meat with a strong focus on hygiene, food safety and good working conditions."

Guests entering the plant will have an impressive experience. After an introduction movie about Harim in the company cinema, the film screen will lift to give access to the Harim museum and information center. A 500 meters (1,640 ft) long visitors' corridor shows the production process and provides a complete overview of the Marel poultry processing lines.

Marel is proud to be the main partner in this prestigious project, bringing poultry processing literally to new heights!