StreamLine has certainly improved our business performance

Danny Sedra

VP of Operations at Central Bernard

Les Viandes Central Bernard, a Montreal-based poultry processor, uses Marel’s StreamLine and AXIN software solutions to achieve real-time monitoring and labor continuity, leading to higher throughput and more predictable production. During Marel’s Software Knowhow event in Orlando, Florida, in October 2024, Danny Sedra, VP of Operations, discussed the challenges Central Bernard encountered, and explained how things have improved since the implementation.

As a prominent player in the North American poultry processing industry, Les Viandes Central Bernard faced significant challenges in market competition and operational production optimization. The company encountered issues with productivity and workforce reliability. “We struggled with consistency and throughput, especially with employee attendance being unpredictable from one day to the next,” explains Danny Sedra.

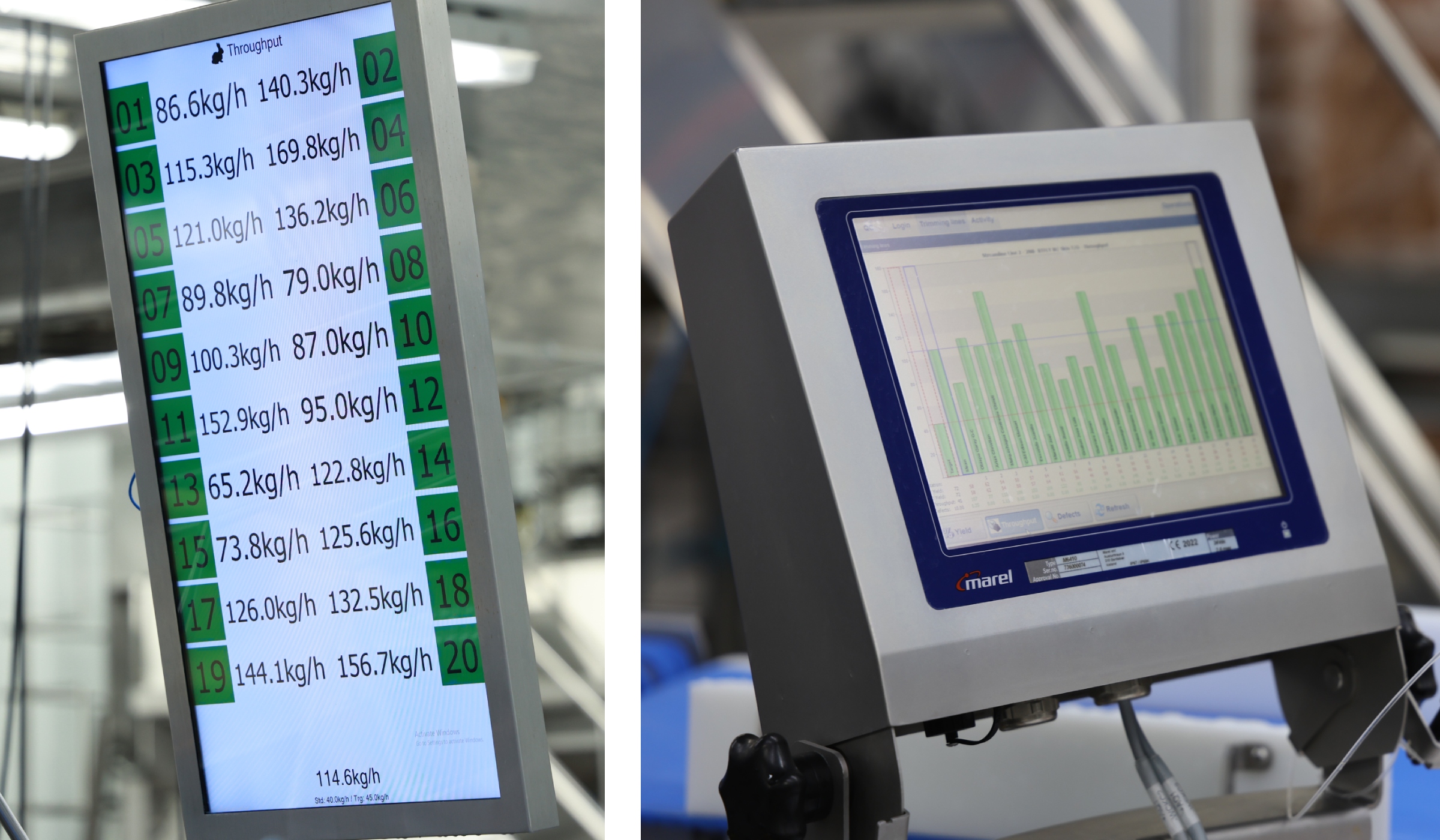

In search of a solution, Central Bernard partnered with Marel and implemented the StreamLine system along with AXIN software in the deboning department. “We operate a 50,000 square foot facility. Our throughput on finished product is about 80,000 to 100,000 kilograms per day and we employ a team of about 150 people. About three years ago, we took on this project to improve our processes. After that, together with Marel, we conceptualized the project. We installed two StreamLines with 20 stations each and implemented Marel’s AXIN software.”

In addition to attendance issues, Central Bernard had to deal with significant variations in product size. “We looked at various options, and StreamLine offered the flexibility we needed to handle different product sizes without sacrificing yield.”

With StreamLine’s intelligent deboning and trimming line and AXIN’s real-time data capabilities, Central Bernard has seen dramatic improvements. "Since adopting StreamLine and AXIN, we've boosted our throughput, improved productivity, and ensured more stable attendance," Sedra notes. This upgrade allowed the company to plan more effectively, meet customer demands consistently, and reduce the need for outsourcing labor, all while boosting overall performance.

Before integrating StreamLine and AXIN, Central Bernard’s deboning operators worked as a team and received shared production-based remuneration, despite uneven productivity. With StreamLine and AXIN, Central Bernard can now monitor individual productivity and pay employees based on their performance. “Now, employees see that they work for their own remuneration. They’re motivated, incentivized, and have taken ownership of their throughput.” This shift in mindset has increased engagement and raised wages, as employees now produce more and earn more.

Danny Sedra continues, “Before our project with Marel, we had difficulties planning daily production capacities. We didn't know on any given day how many deboners would be at work, and we could never predict the speed of their work, which made it difficult to commit to accepting orders. As a result, we adopted a very conservative approach in that regard and had to outsource our deboning capacity or buy in product to compensate, which costs money. When customers asked us, ‘We need these products in any given week,’ we couldn't do that.

But now that we've gotten consistent throughput, it really facilitates planning. We're able to calculate how much we can produce each day, and that's because the overall rate of production is very consistent. So we've adopted a more aggressive approach to order-taking. We commit to higher volumes and even look for more. In the end, the StreamLines have given us more capacity in the same square footage with the same labor force. They have certainly improved our business performance."

StreamLine has certainly improved our business performance

Danny Sedra

VP of Operations at Central Bernard

The introduction of AXIN software has given Central Bernard real-time insight into productivity and yield. “Before StreamLine and AXIN, we had a reactive approach—too little, too late in terms of visibility,” Danny Sedra explains. “Now, we have live data sharing through dashboards that display KPIs, performance lights, and automated daily reporting.” With this data-driven approach, Central Bernard provides employees with a leaderboard showing individual yields, encouraging healthy competition and accountability. “When we started, the gap between the best and worst yields was 12-15%. "Now, we’ve compressed that to between 4-5%,” says Danny Sedra, crediting this improvement to the feedback and insights enabled by AXIN.

With the consistent throughput and productivity gains provided by StreamLine and AXIN, Central Bernard is well-positioned to expand operations and take on higher order volumes. Danny Sedra states, “It allows us to futureproof our operation for the next generation, making us more competitive and resilient in the marketplace.”

Central Bernard’s success with the StreamLine and AXIN solutions has been supported by Marel’s responsive and knowledgeable team. “Our Marel sales representative, David Lamontagne, has been there with us from the beginning and has been instrumental in our success,” Danny Sedra concludes. “When there’s an issue, we can easily call him, and he’s always there to help us out. It’s like a true partnership.”

With Marel’s support and technology, Central Bernard has positioned itself to continue providing high-quality, value-added poultry products while building on its legacy of innovation and excellence.

It allows us to futureproof our operation, making us more competitive and resilient

Danny Sedra

VP of Operations at Central Bernard

Les Viandes Central Bernard, established in 1962, has become a prominent player in North American poultry processing, producing a wide range of high-quality chicken products. The company specializes in processing fresh, frozen, and value-added poultry items, including whole birds, cuts, and marinated products, which cater to both retail and food service sectors. Their commitment to quality, safety, and customer satisfaction is central to their operations, and their products are known for meeting the highest standards in the industry. Serving customers across North America, Central Bernard has built a loyal base of partners, including grocery chains, food distributors, and restaurants. As part of their commitment to innovation, the company has continuously invested in state-of-the-art processing equipment, including advanced Marel machinery, which enhances efficiency, improves product consistency, and ensures food safety. This focus on technology allows Central Bernard to stay competitive in a dynamic market while maintaining their reputation for excellence. Led by a second-generation family team, with the third generation now involved, the company remains agile, adapting to changing market needs while fostering long-term relationships with both customers and employees.

Our dedicated team is here to help and answer any questions you may have. Please complete the form, and we’ll get back to you as soon as possible. We look forward to hearing from you.