We were able to keep the same team but essentially double our output

Valérie Sanchez

Administrative Director at Pac-Rite

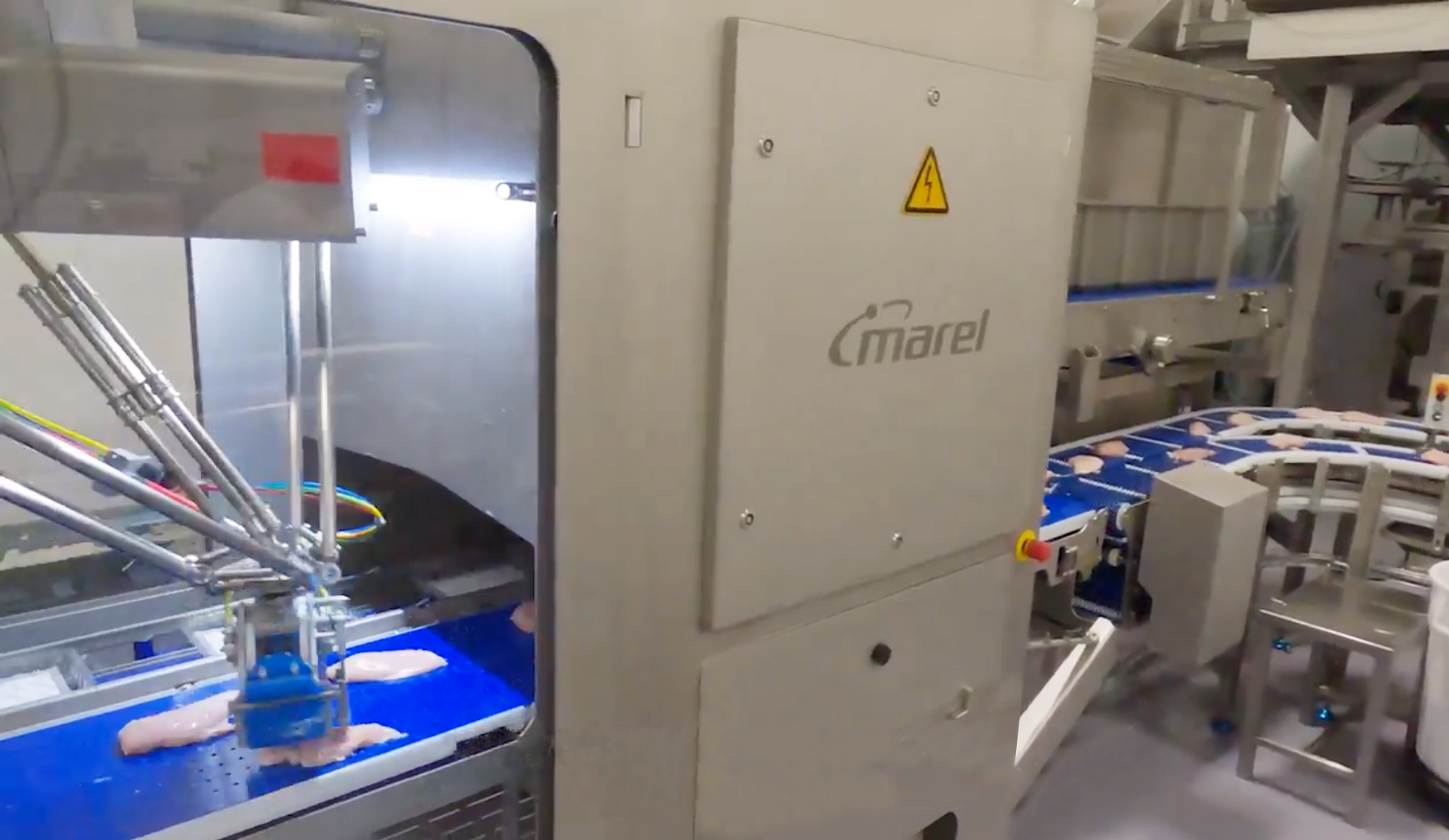

Pac-Rite Meat Products Inc., founded in 1954, has elevated its operations by investing in Marel’s RoboPacker, a cutting-edge tray-packing solution for the poultry industry. Kevin Sanchez, Director of Operations, and Valérie Sanchez, Administrative Director at Pac-Rite, discuss the company’s evolution, its focus on innovation, and how the RoboPacker has transformed the packing process to meet modern demands.

Seventy years ago, Pac-Rite Meat Products began as a small butcher shop on Montreal’s Papineau Street, delivering high-quality meats to local households. "We're the third generation at Pac-Rite," shares Valérie Sanchez. "After our grandfather bought into the company, our father took over the business, and now Kevin and I are continuing the legacy."

Innovation has always been at the heart of Pac-Rite's success. "One of the core values of the company is innovation, and that's why the project with Marel was so interesting to us," Valérie explains. "We've been taught to always think about how we can make things better, how we can make the employees' job easier, and improve our productivity. That's how our father brought the company to where it is today."

We were able to keep the same team but essentially double our output

Valérie Sanchez

Administrative Director at Pac-Rite

With rising sales, Pac-Rite’s manual tray-packing line became a bottleneck in the production process. “It was actually the line where we were the least automated for the longest time,” says Kevin. To streamline this critical area, Pac-Rite partnered with Marel and integrated the RoboPacker. “We wanted an automated process to support higher throughput with less labor and stay competitive in the market,” Kevin explains.

Marel provided invaluable support from initial planning to on-site training, ensuring a smooth transition to automation. “Their expertise helped us with the layout and integrating the full line before and after the actual robot,” says Kevin. “We felt well-supported throughout the process.”

The RoboPacker has transformed Pac-Rite’s operations, nearly doubling their output while requiring fewer employees. “We were able to keep the same team but essentially double our output,” says Valérie. Tasks became simpler, and supervision of the line became easier with Marel’s design improvements. “It’s much easier to feed the robot than to manually place products in trays, which has led to operational improvements across the board,” Kevin added.

The RoboPacker supports Pac-Rite’s food safety standards by reducing manual handling, lowering contamination risks. “With the denester before the RoboPacker, we’ve minimized that contact, which really reduces potential hazards,” Kevin notes. The system’s versatility allows Pac-Rite to handle various poultry products and create visually appealing, dense packs that meet customer expectations.

Robotics are becoming more and more important in our operations.

Kevin Sanchez

Director of Operations at Pac-Rite

For Pac-Rite, the RoboPacker is just the beginning of a journey into robotics. “We’re getting into a phase where robotics are becoming more and more important in our operations,” Kevin shares. This partnership with Marel has laid a strong foundation, enabling Pac-Rite to lead in efficiency and quality. With Marel’s RoboPacker, Pac-Rite is set to continue its growth journey, embracing innovation to remain at the forefront of poultry processing.

Company website: pacrite.ca

Our dedicated team is here to help and answer any questions you may have. Please complete the form, and we’ll get back to you as soon as possible. We look forward to hearing from you.