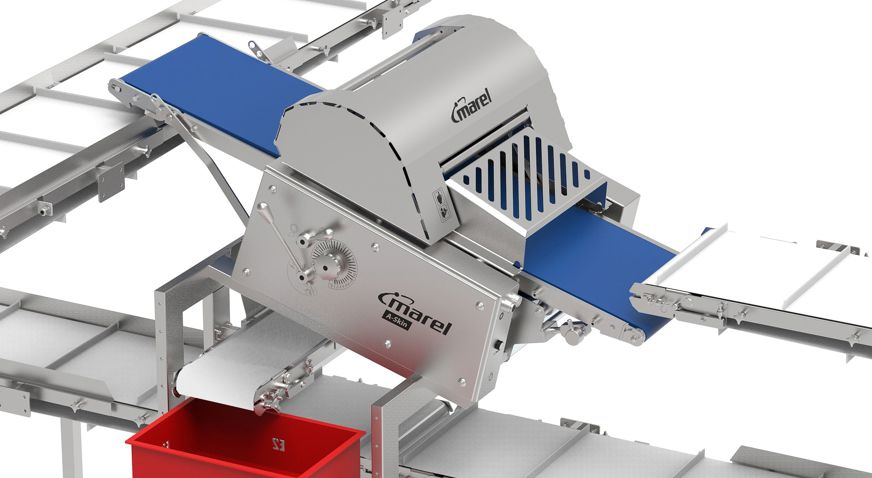

At Marel, we are dedicated to developing solutions that optimize processing in order to tackle these challenges head-on. Our latest innovation is the A-Skin, the first automatic derinding skinner developed from the combined strengths of the MAJA and Townsend brands, both a part of Marel. Discover the five key reasons you will want to have this state-of-the-art machine in your line and find out how its unique features can help you successfully navigate the challenges faced in pork processing with unparalleled success.