Automation wins every time

An automatic process is much more flexible than a manual one. In many countries of the world finding people willing to work in a processing plant is difficult if not impossible. People are also often expensive, particularly when it comes to skilled tasks such as deboning breasts and legs.

Automatic deboning systems can handle much higher hourly throughputs. It is also easy to reduce or increase these to match demand from the market. Much higher productivity means lower costs per unit deboned, making automatically deboned meat more accessible both as a raw product for sale retail and as a base for further processed items.

Flexible cut-up

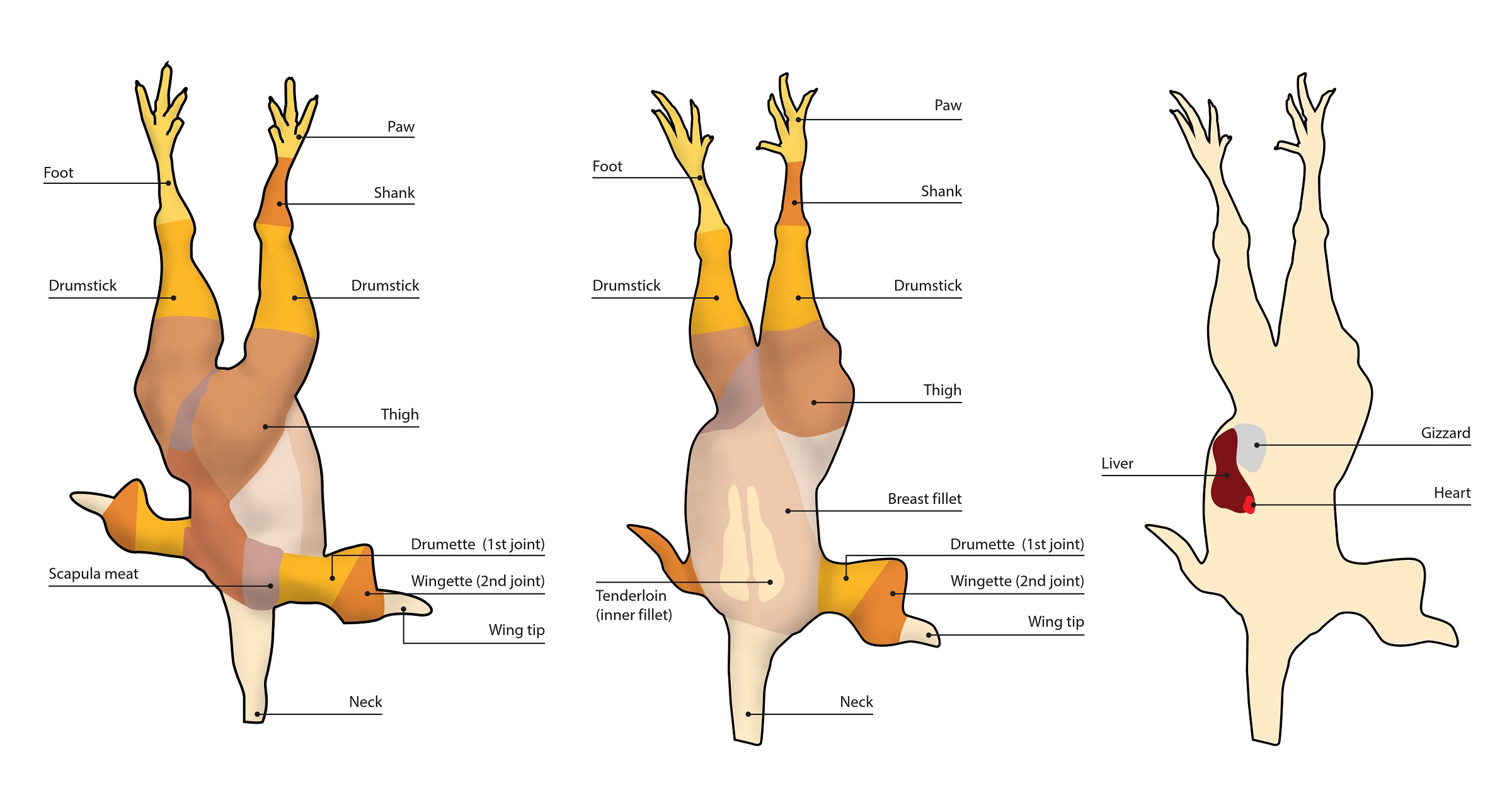

Anatomy limits the possibilities for perfect carcass balance, as products can only be cut and deboned in a finite number of ways. Today’s modular cut-up and deboning systems offer processors the option of making the widest possible range of end products within the constraints set by Mother Nature. To give further flexibility when programming its cut-up system, Marel splits products into wing, front and back half components. Each is then allocated its own cutting regime.

Although live bird supply (the “push” factor) is relatively inflexible, processors have access to the information and automation to help them make the best of things.

Finding new markets

When it comes to the “pull” factor, the marketplace comes to the fore. In the USA, Europe and Oceania breast meat reigns supreme; in Far Eastern markets consumers prefer leg meat. Wings are very popular in the USA. In Brazil the most valuable part of a chicken is its heart. In South Africa drumsticks are a hot item.

Increasing consumer openness to new tastes brought about by cheaper and easier foreign travel, the “globalization” of fast food and media interest in “cooking” is, however, slowly changing things. Leg meat is becoming ever more popular in traditional breast meat markets, even in the USA, where top restaurant chefs now use more leg meat than breast meat in their dishes.

International fast food chains are introducing Asian customers to products made from breast meat. Changing tastes is, however, a slow process. Achieving carcass balance will still mean finding a market for those parts of the product, which are relatively “unwanted” at the time they are produced.