Crumb transport

The RevoCrumb is designed to handle coarse coatings such as dry panko and cornflakes, which are more fragile and prone to breaking down than finer coatings like flour breading. While traditional crumb coating machines use auger screws, we found these unsuitable for the RevoCrumb as they tend to grind and damage the crumbs. To avoid this, we designed a unique wheel mechanism that gently scoops and transports the crumbs without mechanical strain, thereby maintaining their size and texture.

Moreover, because crumbs flow freely, the RevoCrumb features a bunker that allows them to descend gently using gravity, without the need for mechanical force. This method not only minimizes breakdown of particle size but also improves coating quality by ensuring uniform adhesion to the product.

Unique blow-off system

One of the major challenges in crumb coating is that loose particles fall off the product and accumulate in the fryer, which can leave unsightly dark spots on your product. They also soak up valuable frying oil and introduce impurities that can create an unpleasant flavor and shorten your oil’s lifespan.

To address these issues, our dry-coating machines feature a unique blow-off system that reduces loose particles in the frying oil by up to 80%. This innovation improves product quality and saves costs by decreasing the amount of oil exiting the fryer with the crumbs, extending your oils’ lifespan by reducing oxidation, and minimizing black spots on your end products.

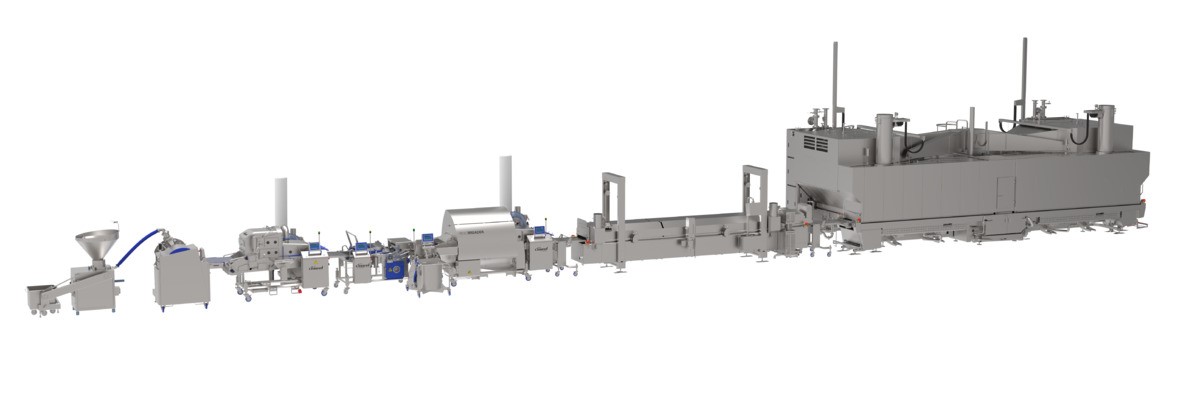

Part of a full-line solution

As part of a comprehensive full-line coating solution, the RevoCrumb works seamlessly with other equipment. It follows the Active Batter Applicator, which expertly coats the product in batter before delivering it to the RevoCrumb. Together, these two machines effectively eliminate belt marks on the underside of the product, ensuring a flawless presentation every time. The RevoCrumb’s adjustable pressure rollers and vibrating plates also enhance crumb adhesion and pickup, significantly increasing yield. This integrated approach ensures a smooth, efficient and high-quality coating operation.