Planning and partnerships are everything

Implementing a food processing MES solution can have tremendous benefits for your organization, but careful planning is needed to ensure that it provides the results you want.

Implementing a food processing MES solution can have tremendous benefits for your organization, but careful planning is needed to ensure that it provides the results you want.

A manufacturing execution system (MES) is used to measure, manage, and control critical plant floor and production activities in real-time, serving as a bridge between the plant floor and the rest of the organization.

A successful food processing MES solution enables food producers to manage and respond swiftly and appropriately to changing conditions, with tangible benefits including:

MES solutions are becoming essential to manage and process data in today’s food industry landscape of ever-increasing demands. While the advantages can be enormous, thorough planning is vital for a successful implementation process.

In this article, we explore the most important considerations when choosing and implementing an MES solution, and how a close partnership with your solution provider can ensure your company reaps the fullest benefits.

Want to learn more about how an MES solution can benefit your business? Our consultants are ready to advise you, with no strings attached.

Talk to a specialist

The key to a successful MES implementation is to comprehensively plan the entire process from start to finish, with a special focus on the four following considerations.

An MES solution can deliver its maximum value by providing a vertically integrated architecture across your organization.

You can help to ensure total integration in ways such as:

Once your company has chosen an MES solution, it’s imperative to get everyone to buy in to the project and work together to enact the necessary changes. Your team needs to understand the MES solution as a tool to facilitate improvement as opposed to a tool simply used to measure operator performance.

Your management team can encourage buy-in by:

Implementing an MES solution will affect your entire organization, its information flow, and its processes. This is why you must have a formalized change management plan to help your staff adapt and address any issues that may arise.

Steps towards effective change management include:

While it may seem appealing to complete the MES project as quickly as possible, your chances of success actually increase in proportion to how much time you spend on it.

You can help to ensure a suitable time frame by:

A good MES solution provider will serve not only as a vendor but as an ongoing partner. It will provide the expertise your company needs to make sure that the implementation process runs smoothly and that your MES delivers the desired results.

However, the solution provider cannot be solely responsible for execution as the stakeholders within your organization also need to contribute. Both parties bring necessary skills and knowledge to the project, so collaboration is essential.

You can help to ensure a successful partnership by:

While each installation has its own unique needs and characteristics, there are two key issues that every company must address.

Before anything else, your company must define precisely what it intends to achieve by implementing a food processing MES solution. These objectives will shape every step of your MES implementation process, and it helps if they form part of a larger business improvement strategy such as continuous improvement, lean manufacturing, Six Sigma, reliability-centered maintenance (RCM), etc.

Your MES solution provider should be your full partner throughout your MES journey. It is therefore crucial to select the right solution provider based upon their experience in the food processing industry, technology, and understanding of the end users’ objectives and business processes.

There are also substantial benefits to selecting a company that can provide a complete array of services as opposed to merely software. Such solution providers can ensure that you can expand your MES solution to your entire enterprise without redevelopment and with a low total cost of ownership. Good solution providers can also provide training as required.

With over 30 years of experience in delivering systems to our customers worldwide, Marel’s Innova software experts bring the practical experience, technology, and professional services you need to secure a successful MES journey. From the first steps of planning to longterm expansion, we want your company to get the maximum benefits from your Innova Food Processing Software and will work in close partnership to help you achieve your most ambitious goals.

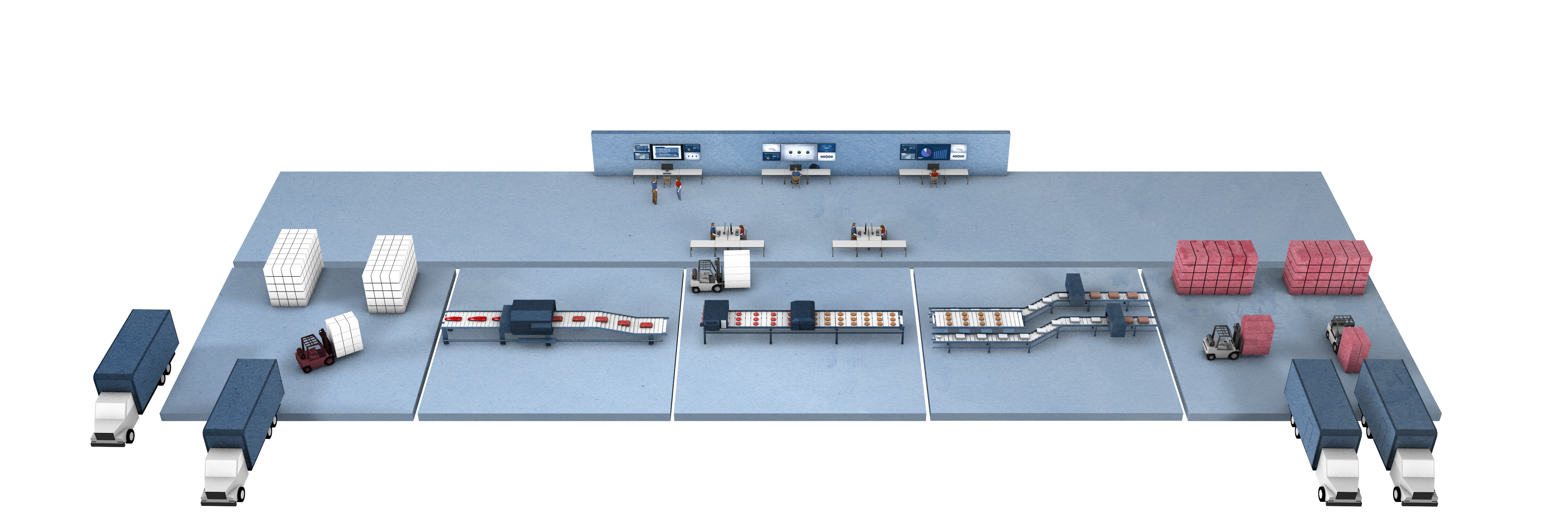

Our Innova manufacturing execution system (MES) software links together processes for internal logistics (packing and warehousing), planning and optimization, performance management, and quality management. Innova MES software provides tracking and monitoring of every aspect of your processes, from ingredient measurement to production reports. By tying it all together in detailed analysis, our MES software ensures product flow tracking and full traceability during production.

Do you want to find out more about how Innova Food Processing Software can revolutionize your business?

Talk to a specialistOur dedicated team is here to help and answer any questions you may have. Please complete the form, and we’ll get back to you as soon as possible. We look forward to hearing from you.