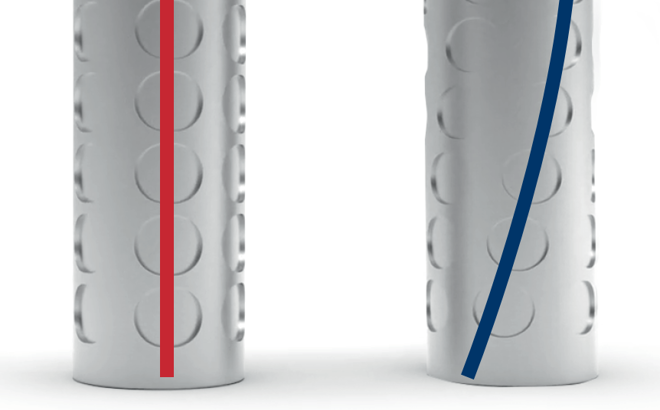

What makes the Helix Drum so unique is the positioning of the product forms on the drum. A classic RevoPortioner drum consists of a number of straight rows of product forms, on a Helix Drum they are positioned along a helix shaped, diagonal line.

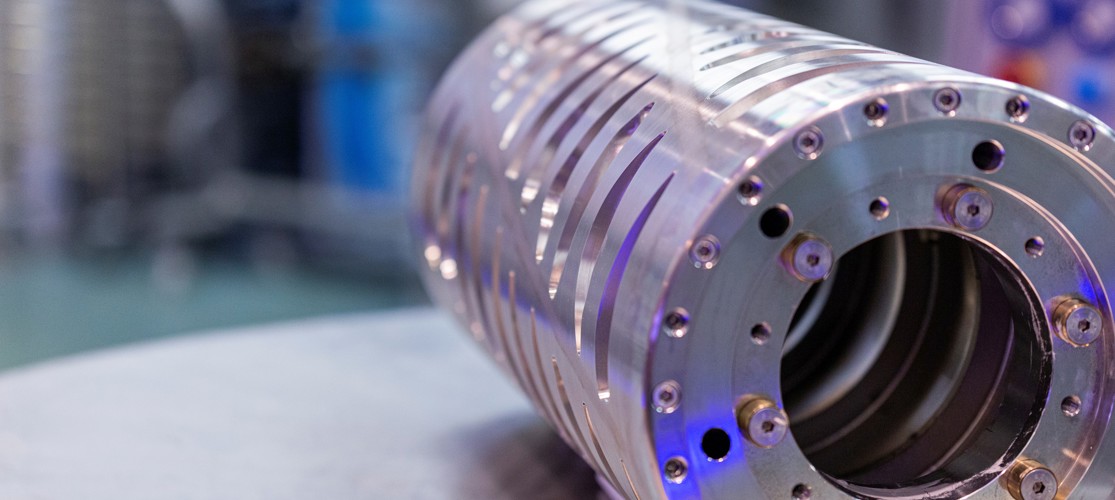

Helix Drum technology: increasing low-pressure forming performance

This patented low-pressure forming technology for the RevoPortioner gives immediate and profitable advantages

Helix Drum technology transforms rotational low-pressure forming into continuous filling. It increases production volumes significantly, produces better quality, more consistent products and gives flexibility to easily expand product portfolios.

Patented technology

Higher production volumes

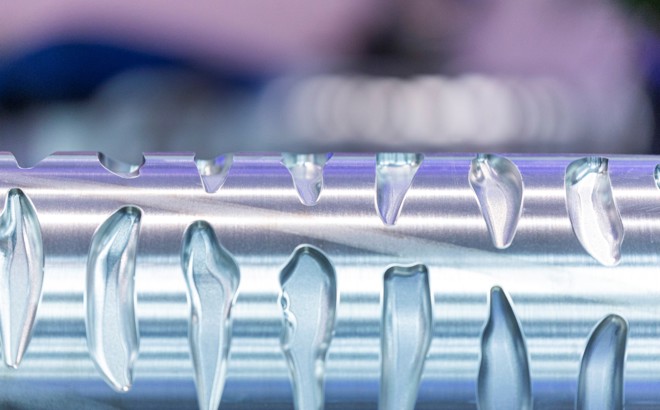

Because the product forms are positioned diagonally in the drum, they can be filled continuously with virtually no start-stop motion. This enables much higher production volumes. Additionally, depending on the size of a product, an extra lane of forms can be added to the diagonal pattern, increasing capacity even further.

More consistent end products

When using a Helix Drum, the flow of the meat is more constant, enabling a more consistent production process. Fewer variations in products across the width of the belt help achieve optimum consistency in both weight and shape.

Less wear and tear

With Helix Drum technology, product forms in the drum are filled continuously. This leads to smaller pressure peaks on the meat pump, which limits wear and tear on the whole RevoPortioner system and gives a more reliable, robust process.

Supporting product development

The X-drum gives you a cost-efficient and highly effective way to develop and trial new products before purchasing additional Helix Drums for your RevoPortioner. The X-drum’s interchangeable segments allow you to do short production runs and easily trial new products thoroughly before making an investment.

Get in touch

Our dedicated team is here to help and answer any questions you may have. Please complete the form, and we’ll get back to you as soon as possible. We look forward to hearing from you.