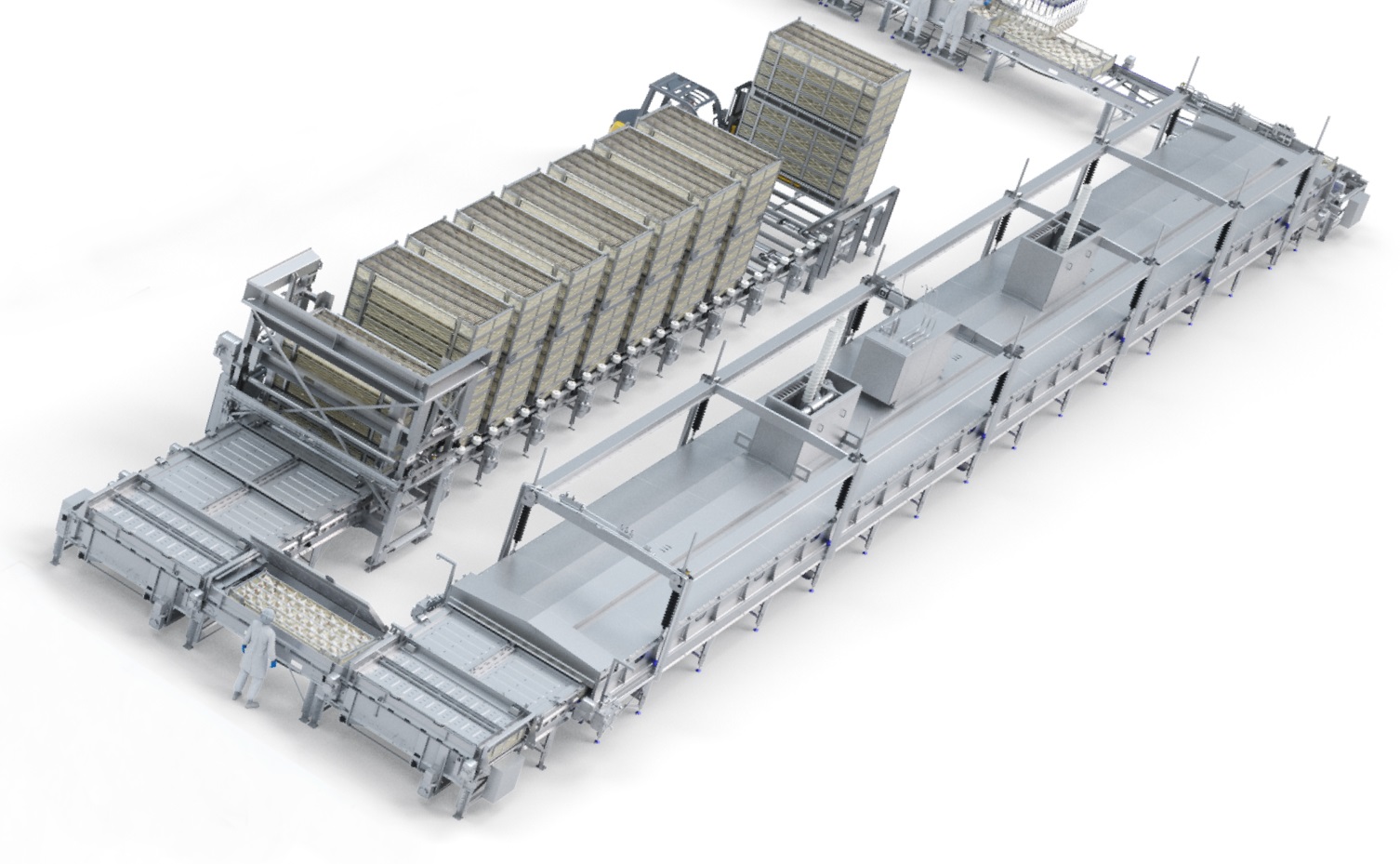

There are many aspects of ATLAS which convinced American processors to turn to this pinnacle of humane live bird handling. It all starts on the farm, where the extremely large opening of the SmartStack transport module makes loading easier for the crew and friendlier to birds. SmartStack trays also feature the most headroom available on the market. AirFlo floors offer plenty of grip, ventilation, as well as drainage for dirt allowing birds to sit dry. All of these characteristics contribute to a smooth, comfortable and safe trip on the truck.

CO2 Footprint

In addition to animal well-being, ATLAS also improves efficiency and reduces CO2 footprint. Despite offering the largest tray height in the industry [27cm, 10.6"], SmartStack can transport the most birds per square foot. This is thanks to the bottom layer, which doubles as a pallet. An important consequence is that fewer truck movements are necessary to transport the same number of birds, emitting less carbon dioxide. For larger poultry processors, cost savings can add up to enormous amounts of money, which can certainly be a decisive argument.

Overall approach

Marel has committed itself to supporting poultry processors in optimizing all steps of live animal handling, even when no equipment is involved. This is an overall approach, with multiple measures available to make the entire process–from catching, loading and transport to arrival at the plant–as unstressed as possible for the broilers. Processors are free to decide for themselves whether they are willing to invest in such a program. This can include covering the sides of trailers with curtains and/or installing a lairage. The lairage option may differ per region. It’s all about imitating the farmhouse environment, offering the birds a similar ‘comfort zone’ with the same conditions as their former habitat. A lairage area can be a temperature-controlled hall, but also an outdoor shelter, as long as it’s protected from cold, heat, wind or precipitation.

Respect and dignity

SmartStack modules are transferred to the ATLAS destacking device. It carefully unstacks all layers tray by tray. Each tray is then conveyed individually and gently towards CAS SmoothFlow. North American processors are committed to ensuring maintenance of the highest standards of animal well-being. All food animals deserve respect and dignity prior to harvesting. Commitment to both ATLAS and CAS SmoothFlow systems reflects this ideal.