Challenge 1: Labor scarcity and employee safety

Labor shortages have severely affected the global food industry in recent years, and the outlook isn’t bright. Finding skilled people has never been tougher, especially given the demanding and risky nature of the skinning process. The A-Skin has an array of special features that combine to let you keep your line running efficiently, safely and with maximum uptime while using minimal labor.

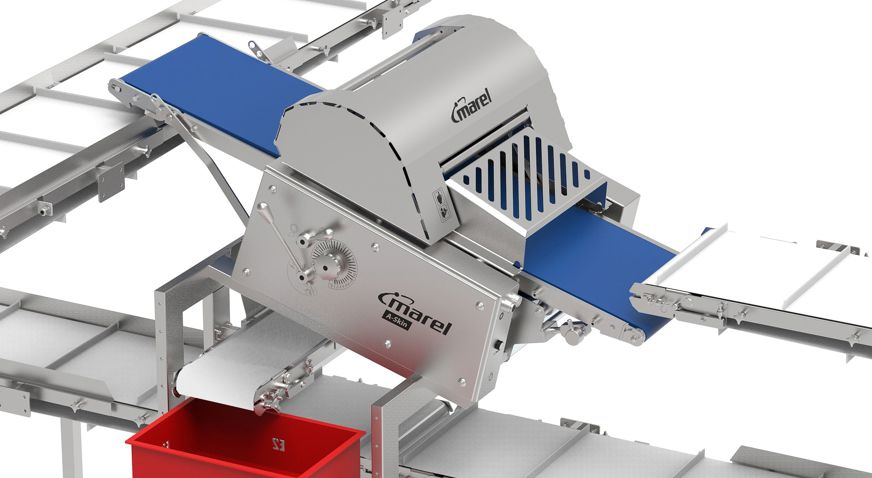

Highest levels of automation

The A-Skin’s high level of automation not only requires less labor, it also ensures higher quality. This results in little or no requirement for rework, so you get increased throughput, improved quality and, crucially, significantly reduced labor costs.

Optimal hygiene – minimal effort

The A-Skin is also highly intuitive to operate, and special features mean almost anyone can perform routine maintenance and cleaning quickly and thoroughly. The folding and swiveling infeed and outfeed belts improve ergonomics and make cleaning the machine easier. The belts remain on the machine and effortlessly swing out, giving full access for cleaning. No tools are needed as manual removal of the individual belts is no longer necessary.

Simpler, safer, more user-friendly

The A-Skin is equipped with an innovative quick-locking device for the blade holder. It brings the blade into position and fixes it in place without needing tools. It also remains permanently in the machine for blade changes and cleaning purposes, ensuring quick changeovers with minimal downtime.